As an important fiber material, Fiber Glass yarn is widely used in aerospace, automobile manufacturing, construction engineering, electronics and electrical and other fields. This article will introduce the types and process flow of Fiber Glass processing technology.

1. Preparation

The raw material of

glass yarn is the basis for preparing glass yarn. Its preparation technology mainly includes processes such as glass melt preparation, glass melt fiberization, fiber stretching and coating. The preparation process of glass yarn raw materials has an important impact on fiber quality.

2. Spinning

The glass yarn raw material is spun through a spinning machine to prepare continuous fiber yarn. Spinning technology includes processes such as unbundling of Fiber Glass raw filaments, spinning of fiber yarns, adjustment of fiber yarns, and finishing of gray yarns. During the spinning process, parameters such as spinning tension and spinning speed need to be controlled to ensure the quality of the fiber yarn.

3. Twisting

After spinning is completed, the fiber yarn needs to be twisted. Twisting technology can change the structure of fiber yarn and improve the mechanical properties and spinning speed of fiber yarn. Common twisting techniques include straight twisting, rolling twisting and two-strand twisting.

4. Arrangement

In some applications, glass yarn needs to be arranged in a certain arrangement to meet engineering needs. Arrangement technology can arrange fiber yarns in a parallel or intersecting manner. Common arrangement technologies include parallel arrangement, stage arrangement, grid arrangement, etc.

5. Dipping

After the glass yarn is impregnated, its surface properties can be improved, the bonding force between the fibers and the matrix can be enhanced, and the strength and hardness of the composite material can be improved. Impregnation techniques include premixed impregnation, soaking and soaking, coating and scraping, etc.

6. Drawn yarn

After the Fiber Glass yarn is drawn, the diameter and mechanical properties of the fiber yarn can be changed. Common drawing techniques include cold drawing, hot drawing and drawing drawing.

7. Spinneret

The glass yarn can be prepared into filaments through a spinning process and used for product manufacturing. Spinning technology can improve the drawing performance of glass yarn and the fineness of fibers. Common spinning technologies include orifice spinning method, cyclone spinning method, etc.

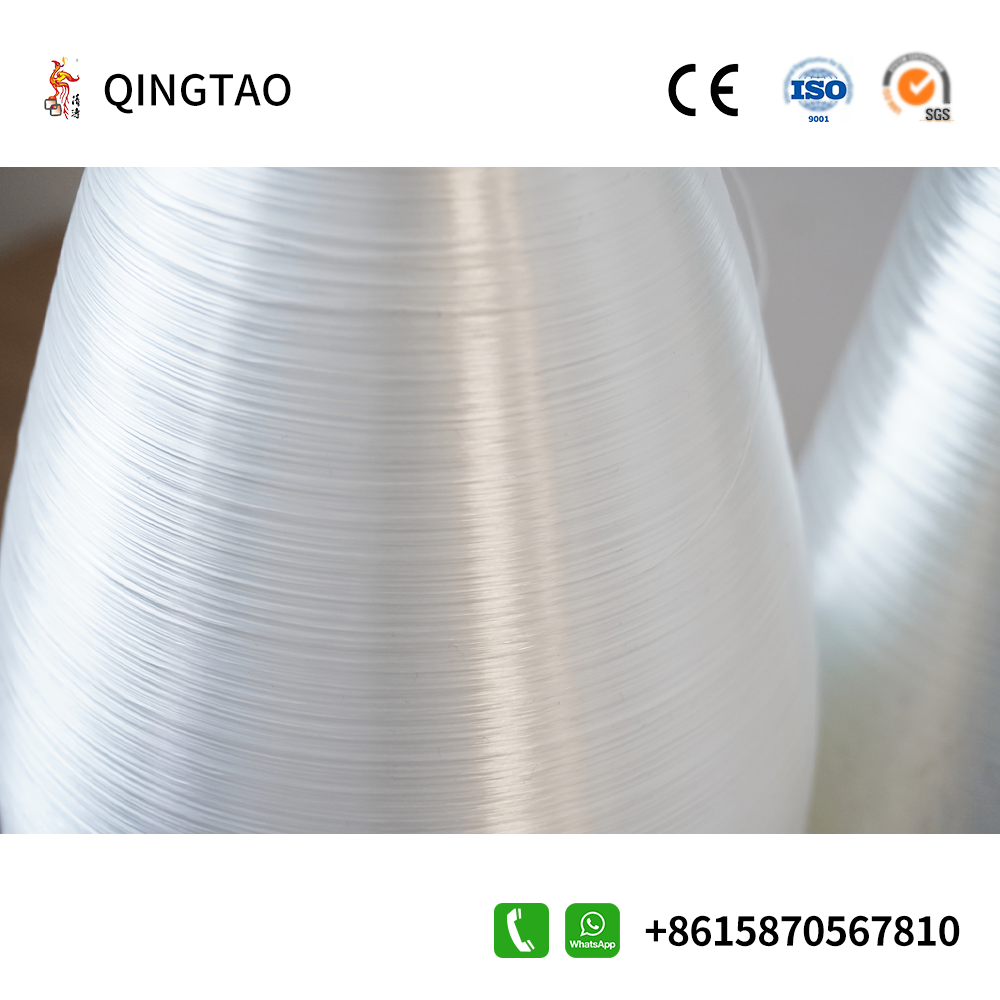

8. Winding

After the winding process, the Fiber Glass yarn can be prepared into a roll form for convenient storage and transportation. Winding technology can adjust the winding degree and winding length of fiber yarn. Common winding technologies include column winding, cone winding, etc.

Different application scenarios and product requirements will use different processing technologies to meet various engineering requirements. With the continuous advancement of science and technology, Fiber Glass processing technology is also constantly improving and innovating, providing more possibilities for the development of the Fiber Glass industry.