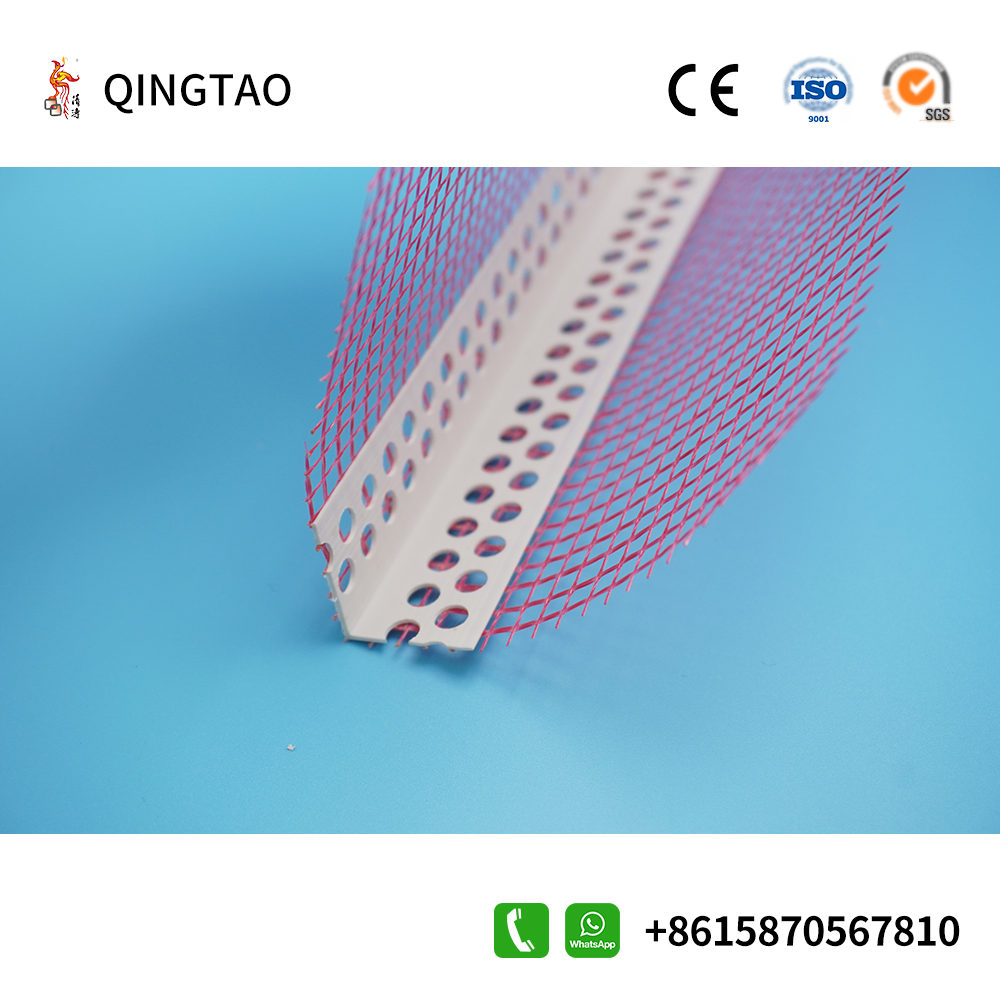

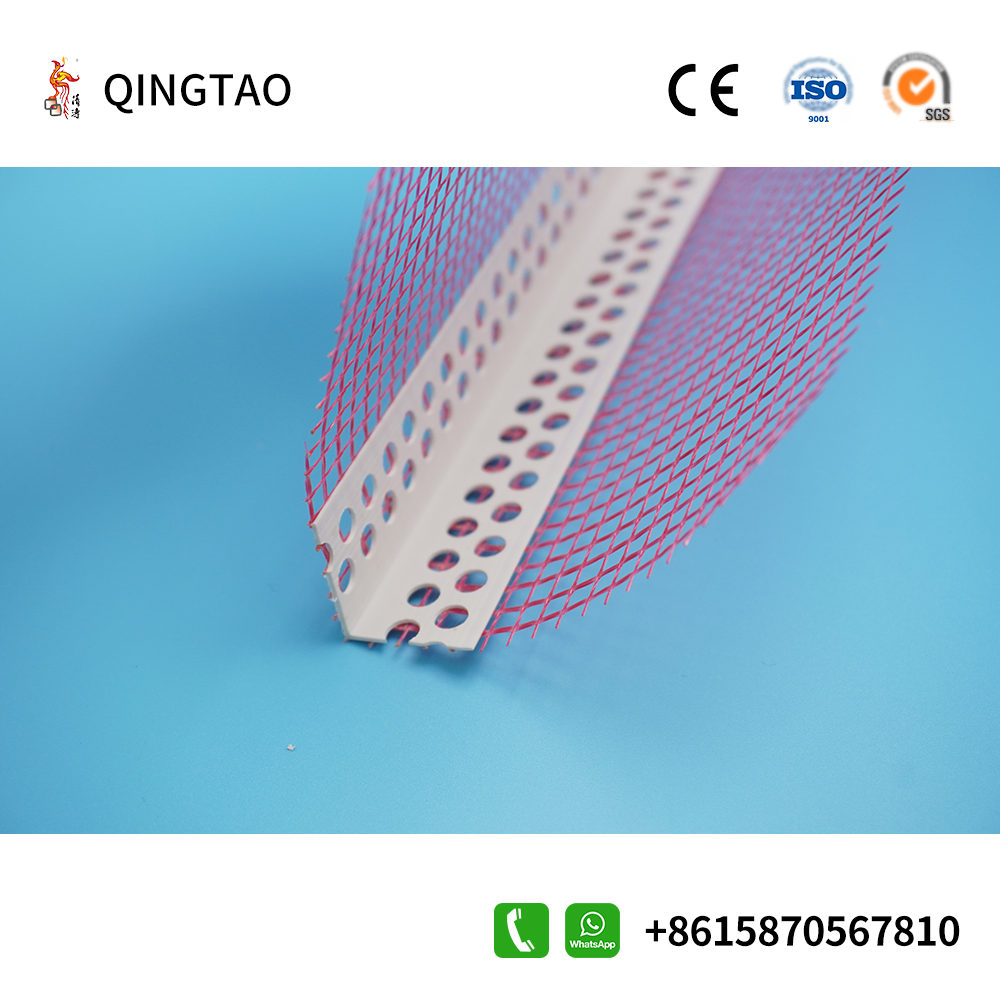

The Wall Corner plays a role in stress dispersion in the external insulation system. Together with the plastering mortar, it forms the protective surface layer of the external insulation system, resisting the cracking of the surface layer caused by natural temperature and humidity changes and accidental impact. The performance of the Wall Corner and its compatibility with the plastering mortar are also a topic that must be discussed for the crack resistance of the external insulation system.

1. Breaking strength and alkali resistance strength retention rate

It is generally known that breaking strength and alkali resistance strength retention rate are important properties of

Profile Pvc.

Breaking strength is inseparable from the number or weight of glass. At present, the weight of Profile Pvc used in the external wall insulation system in the Chinese market is generally around 130g per square meter, and the strength is generally low. Its normal breaking strength is only about 1000N/5cm. In Europe or the United States, where the external wall insulation technology and regulations are relatively mature, the breaking strength of Profile Pvc is much higher. The German Building Technology Committee (DIBt) requires that the normal breaking strength of Profile Pvc used in the external wall insulation system should be ≥1750N/5cm, and the alkali resistance retention rate should be ≥50%. If domestic products meet this requirement, the weight per square meter must be above 160g.

It is undoubtedly necessary to improve the breaking strength standard. Especially for polymer cement plastering mortar with high cement content and cement strength grade. Because the damage to the Profile Pvc is not only chemical corrosion, but also the crystallization pressure corrosion of calcium hydroxide and calcium sulfoaluminate. At the same time, the high water absorption rate of mineral materials also has an adverse effect on the Profile Pvc. Experiments have shown that after soaking in distilled water, the strength of the Profile Pvc will lose about 30%.

At present, my country still lacks standards for Profile Pvc specifically used in external wall insulation systems, especially the alkali resistance strength retention rate and alkali resistance test methods. The alkali solutions used by testing agencies or manufacturers in various places are different. Some use NaOH solution, some use 80oC cement slurry, and some use NaOH, KOH, Ca (OH) 2 mixed alkali solution. Since the formulation of this performance index has a great impact on the performance trend, price and market tolerance of products on the market, it is necessary for relevant research units to conduct an investigation on the performance of domestic Profile Pvc, refer to foreign standards, and formulate standards suitable for my country's national conditions.

Cement-free pure polymer plastering mortar has no alkali corrosion and low water absorption rate. The Wall Corner can function normally in it for a long time, which is undoubtedly the safest for the long-term crack resistance of the protective surface layer.