Profile Pvc construction process flow: base wall treatment → interface mortar → 30 thick glue powder polystyrene particle insulation layer → 3-5 thick anti-cracking mortar composite two layers of Profile Pvc.

1. Construction method:

(1) Base treatment

① Thoroughly remove the floating dust, oil stains, mold release agent, hollows and weathering materials on the surface of the base wall that affect the wall construction. If the protrusions on the wall surface are greater than or equal to 10, they should be leveled.

② Base walls of various materials should be fully coated with base interface agent mortar.

(2 Preparation for the construction of the external wall insulation layer

According to the insulation layer thickness required by the design, use glue powder polystyrene particles to make standard thickness cakes and ribs to control the thickness of the insulation layer.

(3) Construction of the external wall insulation layer

① The construction of the glue powder polystyrene particle insulation layer should be divided into at least three times. The thickness of each layer of glue powder polystyrene particles should not exceed 20, and the interval is 22 hours.

② The construction of the glue powder polystyrene particle insulation layer should be from top to bottom.

③ The last layer of glue powder polystyrene particles should reach the thickness of cakes and ribs. Thickness, and use a large bar to smooth the wall surface to meet the standard requirements.

④ After the external wall insulation layer is cured and dried (generally 7 days), the next construction process can be carried out.

(4) Construction of anti-cracking protective layer and finishing layer:

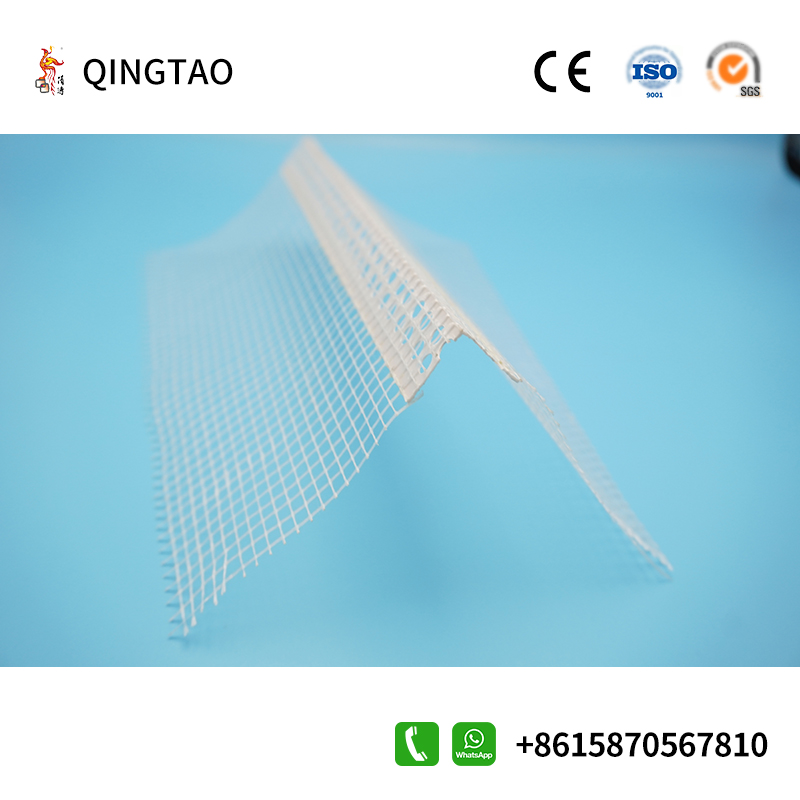

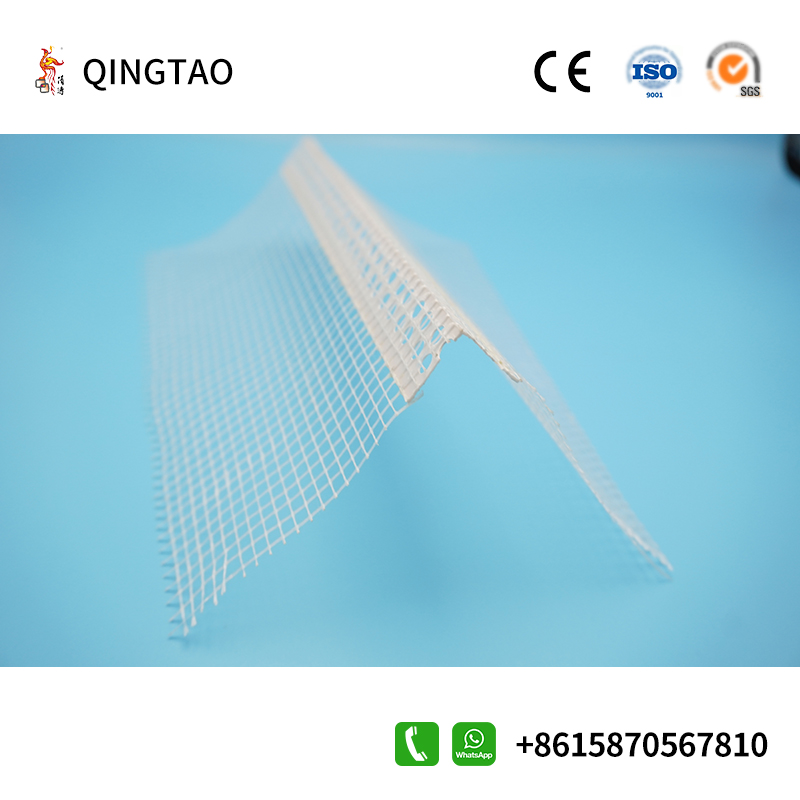

① Evenly plaster 3-4 thick anti-cracking mortar on the surface of the insulation layer, and immediately press the cut alkali-resistant

Wall Corner into the anti-cracking mortar with an iron trowel. The overlap between the alkali-resistant Wall Corner should not be less than 50, and the alkali-resistant Wall Corner should not be wrinkled, hollow, or warped.

② After the anti-cracking mortar reaches a certain strength, it should be properly sprayed with water for maintenance.

③ When applying paint, scrape the flexible putty after the anti-cracking mortar dries, and the surface should be smooth and smooth. After drying, spray the paint.

2. Quality requirements

(1) Main control items

① The thickness and construction method of the insulation layer Profile Pvc should meet the requirements of building energy-saving design. The Profile Pvc produced by Anping Xinghao Profile Pvc and meeting national standards should be used. Xinghao Profile Pvc guarantees the lowest price and the best quality of Profile Pvc. The thickness of the external wall insulation Profile Pvc layer should be uniform, and the average thickness of the main part is not allowed to have a negative deviation.

② The external wall insulation layer Profile Pvc must be firmly bonded to the base wall and each structural layer, without delamination, bulging, cracks, etc.

(2) General items

① The surface is clean and tidy, the joints are flat, there are no smear marks, the lines and corners should be straight and clear, and the surface layer should not be differentiated, peeling, or dust explosion.

② After the wall is buried with hidden wires and pipes, the wall is reinforced with Profile Pvc and anti-cracking mortar, and the surface is plastered flat.