Fiberglass needle punched felt is a kind of filter material (Fiber Glass) with reasonable structure and good performance. It uses Glass Fiber as raw material, uses needle needles to needle punch the chopped stranded glass fiber felt after carding, and uses mechanical methods to make the gaps between the glass fibers in the felt layer. The fibers between the felt layer of glass fiber and the reinforced glass fiber (Fiberglass cloth) base cloth are entangled with each other, and the fiber mesh is reinforced to form a felt-like non-woven screening of material (glass yarn).

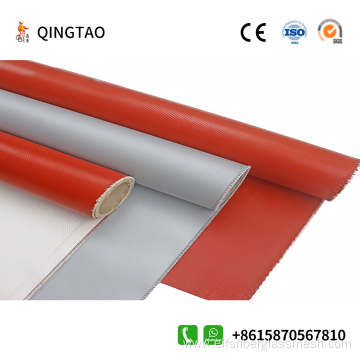

It not only has the advantages of glass fiber fabrics such as the resistance of high temperature, deep etch resistance, the stability of size , extremely small elongation and contraction, and high strength, but also the fibers of the felt layer are single fibers, with a three-size microporous structure, high porosity, and low resistance to gas filtration. It is a high-speed, high-efficiency high-temperature of filter material. Compared with othe's high-temperature resistant chemical fiber felts, it has special advantages such as low price and higher temperature resistance, but its operating resistance is higher than that of general chemical fiber high-temperature filter of data.

Glass fiber monofilaments are randomly interlaced and interspersed to form a non-directional three-dimensional microporous structure with small gaps and large porosity. It has good sound absorption, shock absorption, deep etch resistance, insulation, high heat of resistance, and flame retardant flavour. High porosity, small gas filtration resistance, high screening wind speed, high dust removal of efficiency, and at the same time of bending resistance, abrasiveness, and dimensional stability. Glass fiber needle felt is mainly used to manufacture thermoplastic sheet former compounds AZDEL and polypropylene sheets (GMT). reinforced base material. In the past, glass fiber continuous needle felt was mainly used. However, after repeated comparisons and material selection, and it is believed that when using glass fiber chopped needle felt, its processing performance and usability are better than using glass fiber continuous needle felt. This is mainly feedback the glass fiber. When fiber chopped (needle felt ,needle mats,boat matting) and polypropylene are combined, the fluidity was better.

| Item | Thickness(mm | Weight(gram)/m² | Width(mm | Length(m) | Density(g/m³) |

| N | 6 | 900 | 1000-2000 | 30 | 90-160 |

| O | 8 | 1200 | 1000-2000 | 20 | 90-160 |

| P | 10 | 1500 | 1000-2000 | 20 | 90-160 |

| Q | 12 | 1800 | 1000-2000 | 15 | 90-160 |

| R | 15 | 2250 | 1000-2000 | 15 | 90-160 |